Returnable Packaging In Automotive Industries.

Returnable packaging is an important component of supply chain management in the automotive industry. It refers to the use of packaging materials that can be reused multiple times for transportation, storage, and delivery of automotive components and parts. Returnable packaging offers several benefits, including reduced costs, improved sustainability, and enhanced efficiency. In this article, we will explore the various aspects of returnable packaging in the automotive industry.

Benefits of Returnable Packaging in the Automotive Industry:

1. Cost Reduction:

One of the major benefits of returnable packaging is the reduction in costs associated with transportation, storage, and delivery of automotive components. Returnable packaging materials such as reusable containers, pallets, and racks eliminate the need for disposable packaging, which can be expensive to replace. This reduces the overall cost of packaging, transportation, and storage.

2. Improved Sustainability:

Returnable packaging is an eco-friendly solution that reduces waste and promotes sustainability. The use of reusable packaging materials reduces the need for disposable packaging, which can end up in landfills and cause environmental damage. This contributes to reducing the carbon footprint of the automotive industry.

3. Enhanced Efficiency:

Returnable packaging helps improve the efficiency of the supply chain by reducing the time and effort required for packaging, transportation, and storage. With reusable packaging materials, there is no need to spend time and effort on sourcing, ordering, and disposing of disposable packaging.

4. Improved Product Protection:

Returnable packaging materials are designed to provide maximum protection to automotive components during transportation and storage. Reusable containers, pallets, and racks are durable and can withstand the rigors of transportation, preventing damage to automotive components.

5. Improved visibility:

Returnable packaging management systems provide improved visibility into the supply chain, enabling companies to track the movement of components and packaging materials in real-time. This helps improve supply chain visibility and enables companies to quickly identify and address any issues that may arise.

Types of Returnable Packaging in the Automotive Industry:

1.Reusable Containers:

Reusable containers are a popular form of returnable packaging in the automotive industry. They are designed to transport and store automotive components and parts, and they can be used multiple times. These containers are typically made of plastic or metal and come in various sizes and shapes to accommodate different types of automotive components.

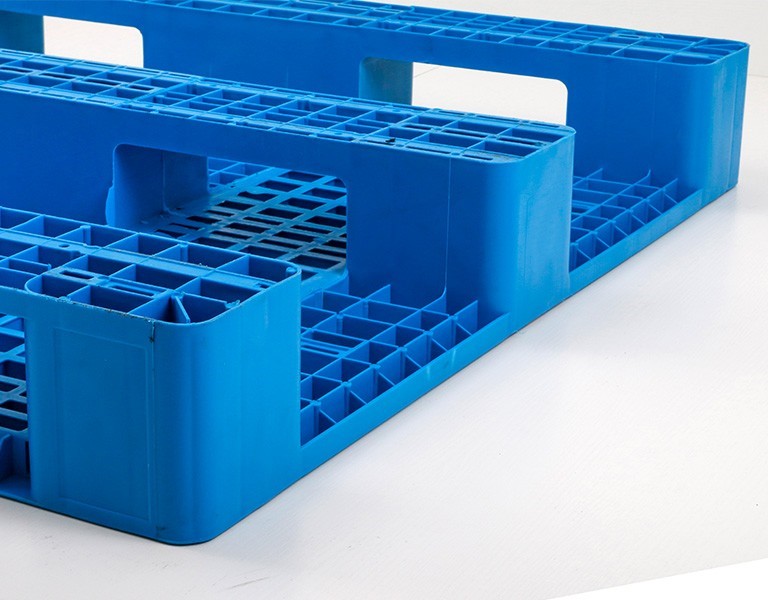

2. Pallets:

Pallets are an essential form of returnable packaging in the automotive industry. They are used to transport automotive components and parts in bulk and are designed to be stacked on top of each other for efficient storage and transportation. Pallets can be made of wood, plastic, or metal and can be reused multiple times.

3. Metal Racks:

Metal Racks are another form of returnable packaging that are commonly used in the automotive industry. They are designed to hold automotive components and parts during transportation and storage, and they can be reused multiple times. Racks can be made of plastic or metal and are designed to fit specific automotive components.

Returnable Packaging Management:

Returnable packaging management is a crucial component of supply chain management in the automotive industry. It involves tracking and managing the flow of returnable packaging materials from the manufacturer to the supplier and back to the manufacturer. This includes managing the inventory of returnable packaging materials, scheduling pickups and deliveries, and ensuring that the packaging materials are in good condition and ready for reuse.

To manage returnable packaging effectively, companies can use specialized software that tracks the location and status of returnable packaging materials in real-time. This helps companies optimize the use of returnable packaging materials and ensures that they are available when needed.

The use of returnable packaging in the automotive industry is not a new concept. In fact, returnable packaging has been used in the automotive industry for many years, and its popularity continues to grow.

To manage returnable packaging effectively, companies can use specialized software that tracks the location and status of returnable packaging materials in real-time. This helps companies optimize the use of returnable packaging materials and ensures that they are available when needed. Additionally, companies can implement processes and procedures to ensure that returnable packaging materials are properly cleaned, maintained, and repaired as needed.

In conclusion, returnable packaging is an essential component of supply chain management in the automotive industry. It offers significant benefits, including cost savings, improved sustainability, enhanced efficiency, improved product protection, and improved visibility. By using returnable packaging materials and implementing effective returnable packaging management processes, companies can optimize their supply chain and improve their bottom line.

Leave a reply