What is POLY BAG

A poly bag is a common shipping and packaging resource made of polymer material that is exceptionally durable, pliable, and customizable to fit any application. Made of polyethylene or polystyrene materials, poly bags are a precisely engineered and designed compact method for protecting and securing products, parts, and merchandise.

The three basic types of poly plastic bags are:

LDPE

Low-density polyethylene

- LDPE bags are characterized by flexibility, tensile strength, and waterproof abilities. They are commonly used for food packaging and cleanroom applications due to their clarity, enhanced flexibility, and supple feel.

LLDPE

Linear low-density polyethylene

- LLDPE is characterized by incredible strength, durability, and puncture resistance. You can use it to accommodate sensitive products, especially since they offer higher tensile strength and durability than LDPE.

HDPE

High-density polyethylene

- HDPE features densely packed molecules delivering a rigid, robust, and durable bag structure. For that reason, HDPE is used for storing large volumes of weight. Additionally, HDPE Bags are opaque, water-, and heat-resistant, meaning that they’re safe for transporting food and sensitive cleanroom applications.

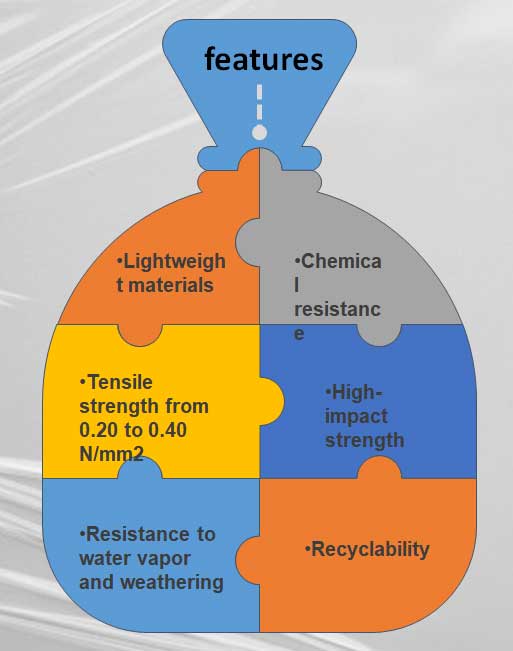

A regular poly bag is any bag made of plastic, and it’s commonly used for packaging and shipping. Poly bags are lightweight, multipurpose, and made from recyclable materials, which limits their environmental impact.

While poly bags are convenient for various industrial and domestic uses, certain customization options are available, as well. You can have a poly bag in different colors and printed logos, which you can use for commercial purposes. Moreover, poly bags are a popular choice for food packaging, but, in that case, they must comply with FDA regulations. Another popular form of poly bags refers to gusseted poly bags, suitable for storing bulky goods and greater quantities than classic, flat bags.